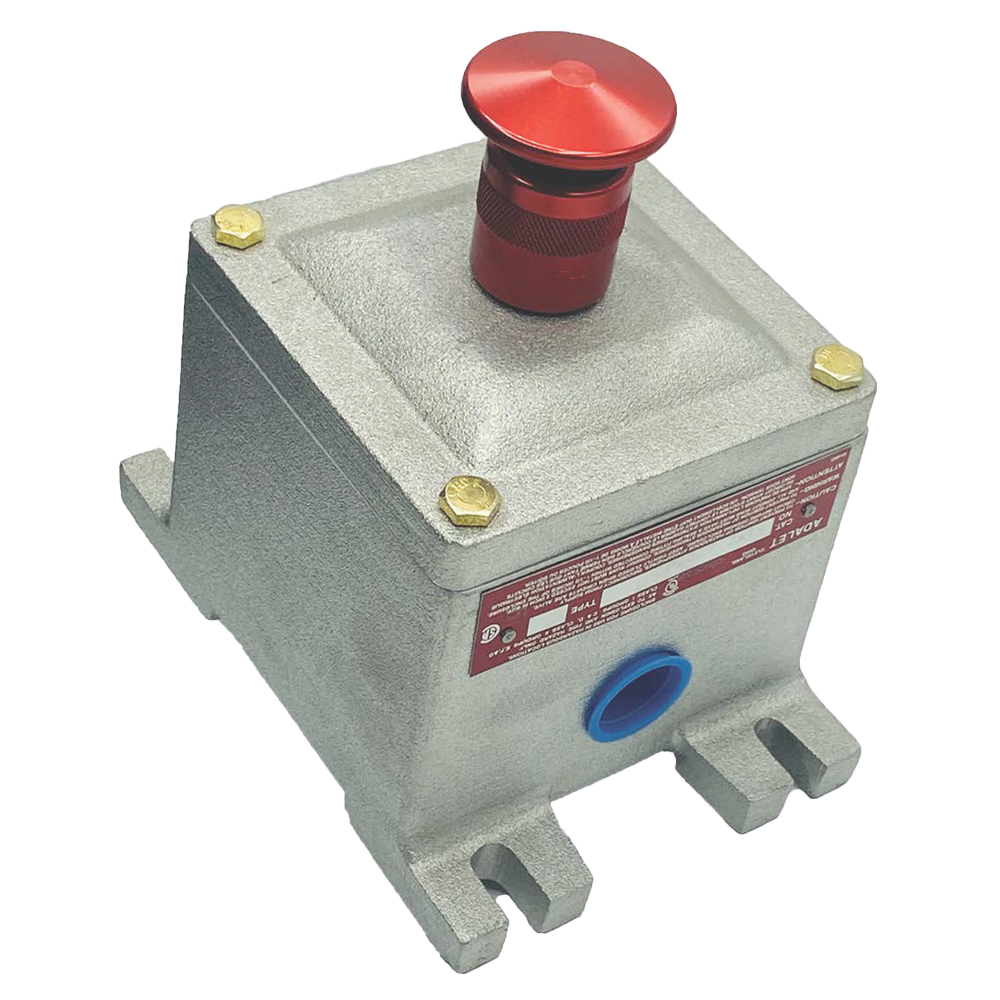

NEMA7 EMERGENCY STOP BUTTONS

Standard Features

• All operators are die cast aluminum alloy. The barrels are all 3/4” NPSM thread. Maximum installation thickness 1 3/4” long barrel, 3/4” short barrel.

• Black molded nylon buttons. The exposed metal parts are black anodized aluminum. For color coding we will furnish at no additional cost the following color combinations: Red buttons with red metal caps and green buttons with green metal caps. Metal caps are also available in blue, gold or clear with black buttons. Specify colors required.

• Red Mushroom head buttons are 1 3/4” diameter anodized aluminum. Also available in black or green.

• For use with BT contact blocks. Contact blocks can be stacked for multiple circuits. Contact blocks are not included with the operators.

• XHPPM/XHPPMS require 2″ minimum spacing.

• XHPP pushbuttons are maintained.

The Enclosure

The NEMA7 Emergency Stops are designed for protection; a pre-assembled kill switch for Division 2 areas, that is functional and preassembled for immediate installation.This assembly is designed to ensure you have a reliable and affordable emergency stop for your equipment, making it ideal for refineries, manufacturing facilities, plants and more.

The Construction

The enclosure is a high-quality polycarbonate outer shell with stainless steel hinges and bolts, a watertight gasket that is NEMA 4 rated for outdoor use. The mushroom head switch is two position, maintained push-maintained pull operator with sealed contact blocks and comes pre-labeled for your convenience and safety.

Standard Features

• Lightweight, corrosion-resistant, copper-free aluminum alloy (0.3% max. copper content).

• All operating shafts are stainless steel for corrosion resistance.

• Durable cast on lugs cannot get lost.

• Ground screw is highly visible and accessible.

• Uniform wall thickness (not ribbed) for versatility of conduit openings assuring 5 full threads engagement and maximum available area for conduit drilling and tapping.

• Operators may be mounted through back wall for panel mounting.

• Box depth provides for the stacking of 2 contact blocks.

• Anodized aluminum operators install easily in the field.

• XHPPM/XHPPMS require 2″ minimum spacing.